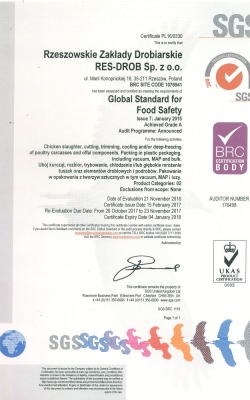

BRC Certificate

BRC Food Certificate is implemented by food companies that deliver food to retailers. International retail chains use the BRC Food as a criterion for the selection and verification of their suppliers and to standardize production. The external audit and BRC Food certification, retailers treat as their own verification provider.

BRC Food Standard integrates the provisions contained in ISO 9000: 2008, the HACCP system and the principles of good manufacturing and hygienic practices: GMP and GHP, at the same time defining the requirements that must be met to ensure the safety and necessary repeatable levels of the final product quality.

Benefits from implementing the BRC Food v. 7 with the help of Pakuła Consulting:

Korzyści z wdrożenia BRC Food v. 7 z pomocą firmy Pakuła Consulting:

- Start of cooperation with the British retail chains;

- Reduction in the amount of external audits carried out by customers;

- Fulfillment of legal requirements on food safety;

- Increased confidence from public administration and customers;

- Improvement in the company's image and product branding;

- Improvement in organization and optimization of processes;

- Improvement in product traceability and identification;

- Ensuring the safety, quality and repeatability of manufactured products;

- Optimization of costs concerning a product out of specification, eventual withdrawals or returns.

Pakuła Consulting company has extensive experience in the implementation of BRC, BRC training and preparation for certification of the BRC. Employees of Pakuła Consulting have auditor qualifications and professional education in food technology, chemistry, polymers, as well as long-term work experience in the food industry and packaging.

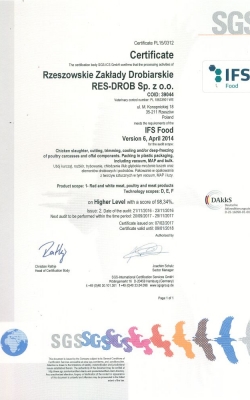

IFS Certificate

International food standard (IFS) was developed to protect the brands of food products.

IFS complies with all requirements of food producers and participants in the food chain, with particular emphasis on food plants providing food to retail chains under their own brand.

IFS norm is not only to ensure high product safety, but also to reduce the suppliers’ and sellers’ costs, and comparable transparency throughout the food production chain. An important element of the standard is the conformity of the products with European Food Law.

Requirements of this standard in respect to the food safety management system combine the principles of GMP, GHP and HACCP - including the elements of the management system according to ISO 9001. There are currently 6 versions of the IFS Food standard published July 1, 2015. Version 6 requirementsaredividedinto 5 chapters:

- The responsibility of senior management - defines the responsibility of senior management, as well as monitoring and improvement of systems in place;

- Quality management system - includes requirements for the implementation of the HACCP system according to Codex Alimentarius and the quality management system including the documentation of both systems;

- Resource management - defines the requirements for humanresources, hygienerequirements, medicalresearch and conditions for the social part of the plant;

- The production process - the most extensive chapter provides reference for the design and introduction of products, sanitary requirements for the production and storage facilities, waste management, traceability, monitoring allergens and GMOs;

- Measurement, analysis, improvement - includes requirements for monitoring temperature / time in production processes, control of the amount of packaged goods, handling complaints, withdrawal of the product from the market and supervision of non-conforming products;

- Protection of food and external controls - includes requirements for food protection, plant safety and external audits.

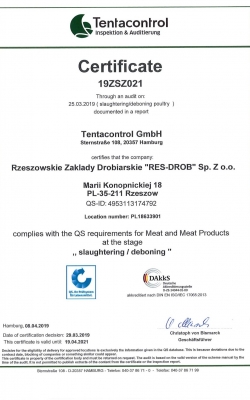

HACCP

Hazard Analysis and Critical Control Points

- the analysis of health risks

- critical control points, established on the basis of the analysis of risks.

The HACCP system was developed to identify and control hazards that may occur at any time during the manufacturing process and storage of food. As a threat understood is anything anything that might bring harm to the consumer.

We recognize the threat by observingeach step of the process of producing food and asking the question "whatcould go wrong" to lead to the production of unsafe food.

The obligation for a plant to implement the HACCP system is regulated by the Act of 25 August 2006 on Safety of Food and Nutrition (Dz. U. of 27 September 2006), which cites and relies among others on the provisions:

- Regulation (EC) No 178/2002 of the European Parliament

- Regulation (EC) No 852/2004 of the European Parliament